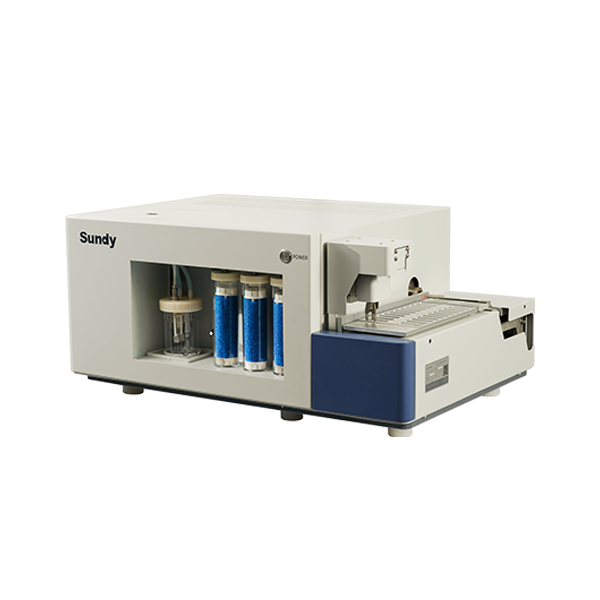

22 samples loaded once, high test efficiency.

Widened crucible, stable temperature zone,high combustion efficiency .

Optimized and upgraded electrolytic cell, extended service life , stable test results for a long time.

Stable and reliable sampling mechanism, low noise.

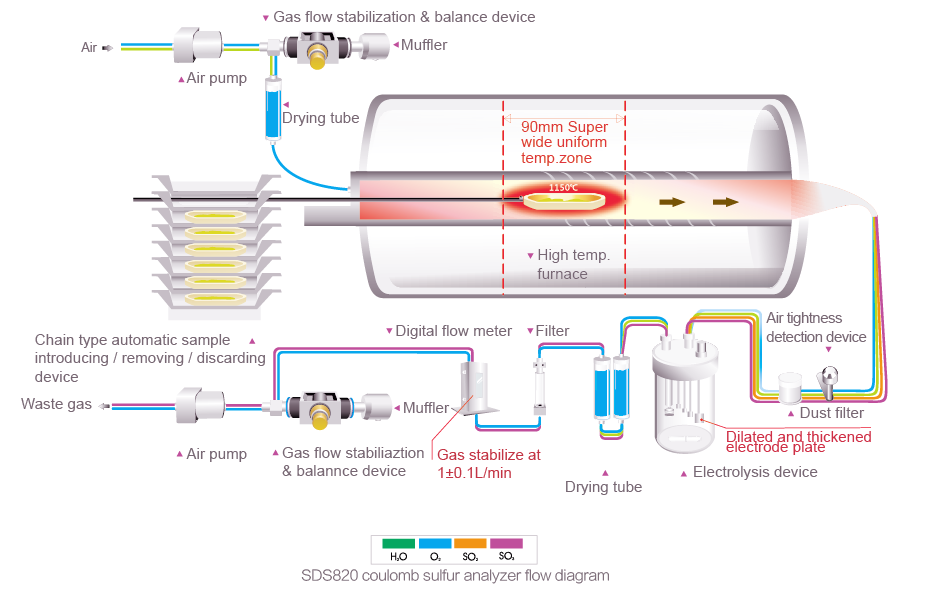

A sample combusts and decomposes in air current with catalyst, the sulfur in coal produces sulfide in the reaction, and among the products, the sulfur dioxide absorbed by potassium iodide (KI) solution . Titrate the iodine produced by electrolyzing potassium iodide, and calculate the total sulfur content in coal according to quantity of electricity consumed when electrolyzing.

The total sulfur content, St, ad, of the sample, expressed as a percentage by mass, is given by the equation below:

St, ad=m1/m×100

Where

St, ad is total sulfur content in general analysis samples, expressed as a percentage by mass, %;

m1 is displayed in coulomb integrator, expressed in milligram, mg;

m is the mass of the sample, expressed in milligram, mg.

Highlights

Accurate, precise and stable test result

1、Optimized system design, full sample combustion, full electrolysis of generated gases and thorough integration ensure accurate results.

2、The double-rod sample delivery mechanism greatly improves the stability of sample delivery;

3、With dilated and thickened electrode plates, electrolysis is more sufficient, integration is more complete, and the test is more accurate;

4、Wide-body crucible design, the sample is in full contact with the combustion-supporting gas, and the combustion is full and rapid.

High automation

1、Chain type automatic sample sending device allows the adding and replacing of samples during test, 22 samples can be loaded once, then all samples’ introducing, testing and discarding are automatic and completed continuously.

2、Two-stage air filter to ensure stable flow for a long time.

Humanization design with stable performance

1、With high quality furnace material, thermal insulation and life time is greatly improved.

2、Unique drying tube with high capacity efficiently reduces the desiccant replacement frequency.

3、Reliable gas pump adopted, longer lifetime and lower maintenance frequency can be obtained.

4、Gas leak check is convenient and fast.

5、The new electrolytic cell leakage and corrosion protection design prevents abnormal leakage from causing corrosion to the instrument;

6、Equipped with silencer, healthy and environmentally friendly.

Specification:

| Description | SDS1200 |

| Test Method | Coulomb Titration |

| Sulfur Determination Range | 0.01% – 40% |

| Standards | ISO20336,GB/T 214-2007 |

| Sulfur Resolution | 0.001% |

| Analysis Time/sample | 3 ~ 5min |

| Preheating Time | ≤30min |

| Max. Quantity of sample | 22 |

| Sample Weight | 10 – 110mg(50±5mg Recommended) |

| Furnace Temp | 1150℃(coal), 900℃(oil) ,1190℃(cement) |

| Heating Elements | Silicon Carbide |

| Temp. Control Precision | ±1℃ |

| Temperature Sensor | Thermocouple |

| Power Requirement | AC 220V(-15% ~ 10%)50/60Hz |

| Max. Power | 3kW |

| Gas Requirement | Air |

| Gas pressure | 14 to 45psig (1 to 3 bar) |

| Sample Introduction and Discarding | Automatic |

| Gas Flow Checking | Gas stabilization and balance device, digital flow meter adopted. Gas flow monitored by software |

| Chemical Reagents | KI、KBr、Glacial acetic |

| Humidity | ≤85% |

| Ambient Temperature | ≤40℃ |

| Operational Control | Windows®-based software on external PC |

| Operation Cost | Lower cost Desiccant: allochroic silicagel |

| Dimensions | 890*610*410mm |

| Weight | 81kg |

| Advance Calculation | Yes |

| Analysis Report | Yes |

| Statistics Report | Yes |

| System Monitor | Yes |

0086-731-88112150 sales@sandegroup.com

0086-731-88112150 sales@sandegroup.com

0086 731 88112150

0086 731 88112150 0086 731 88134650

0086 731 88134650 sales@sandegroup.com

sales@sandegroup.com